- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Model: | |

|---|---|

| Availability: | |

| Quantity: | |

670-130

AIRKING

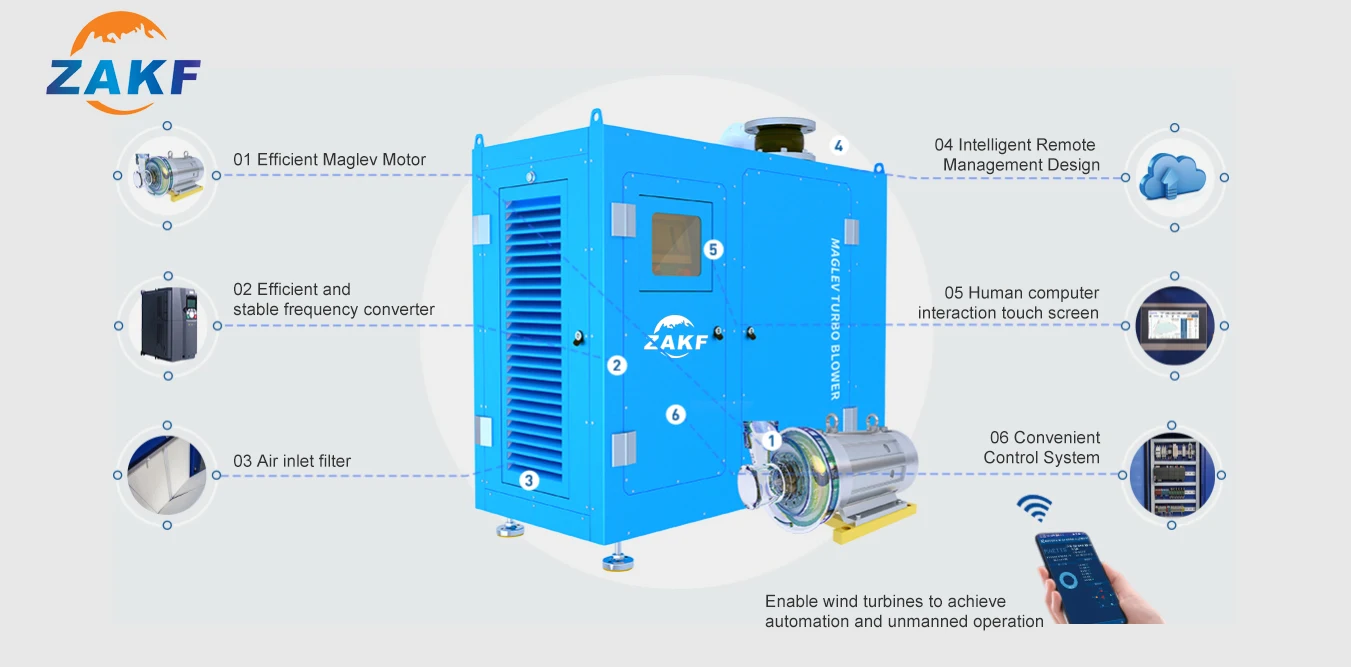

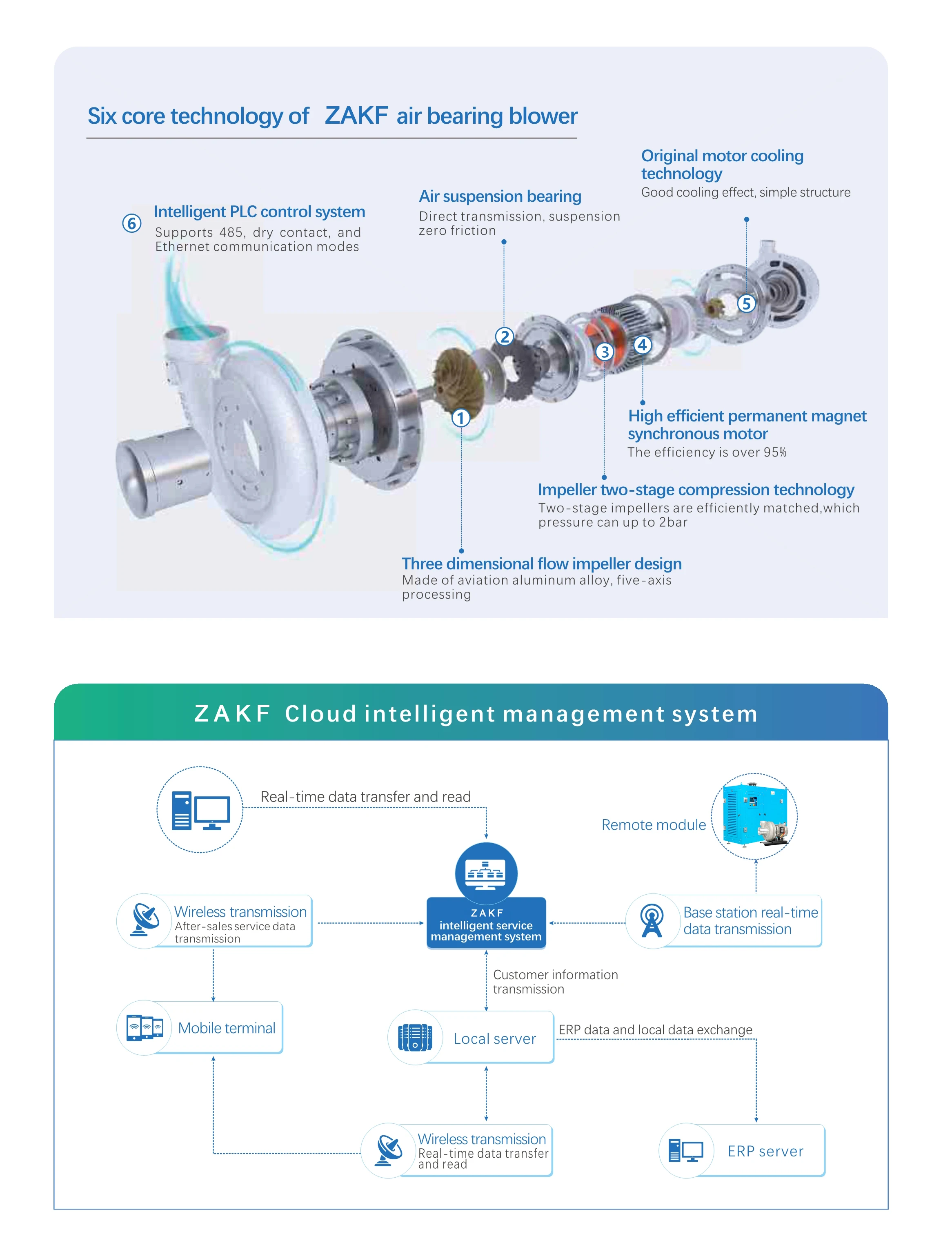

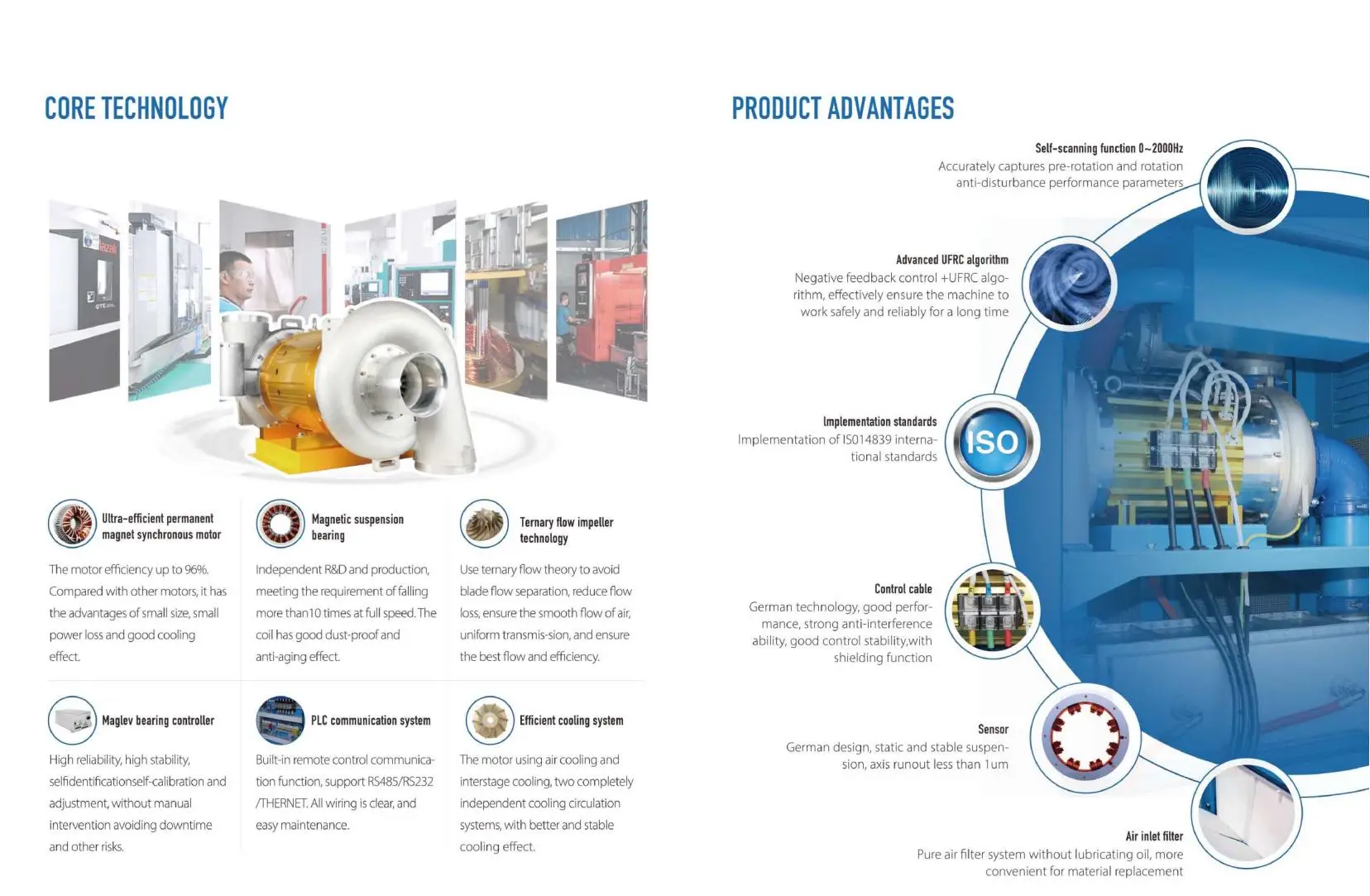

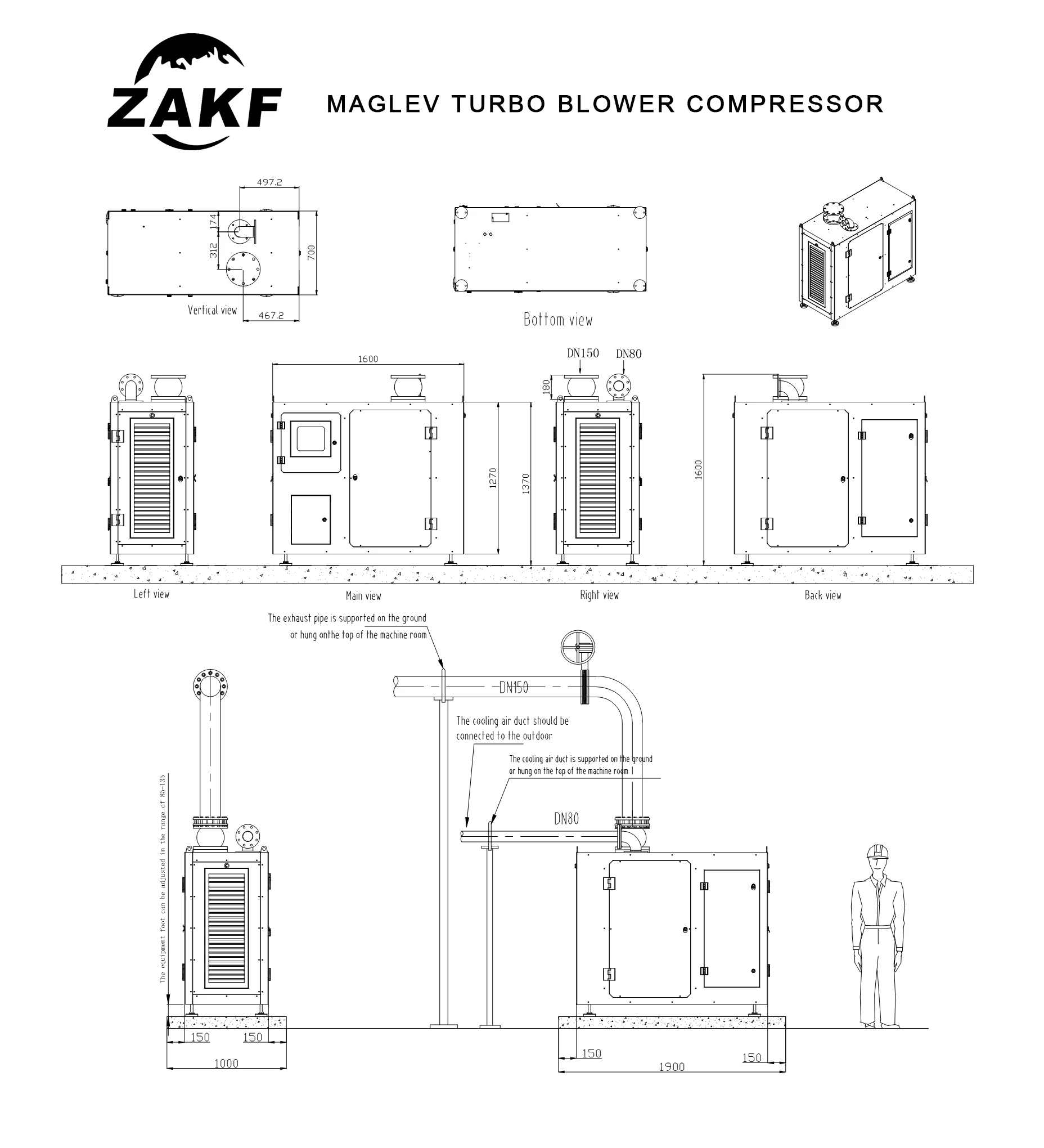

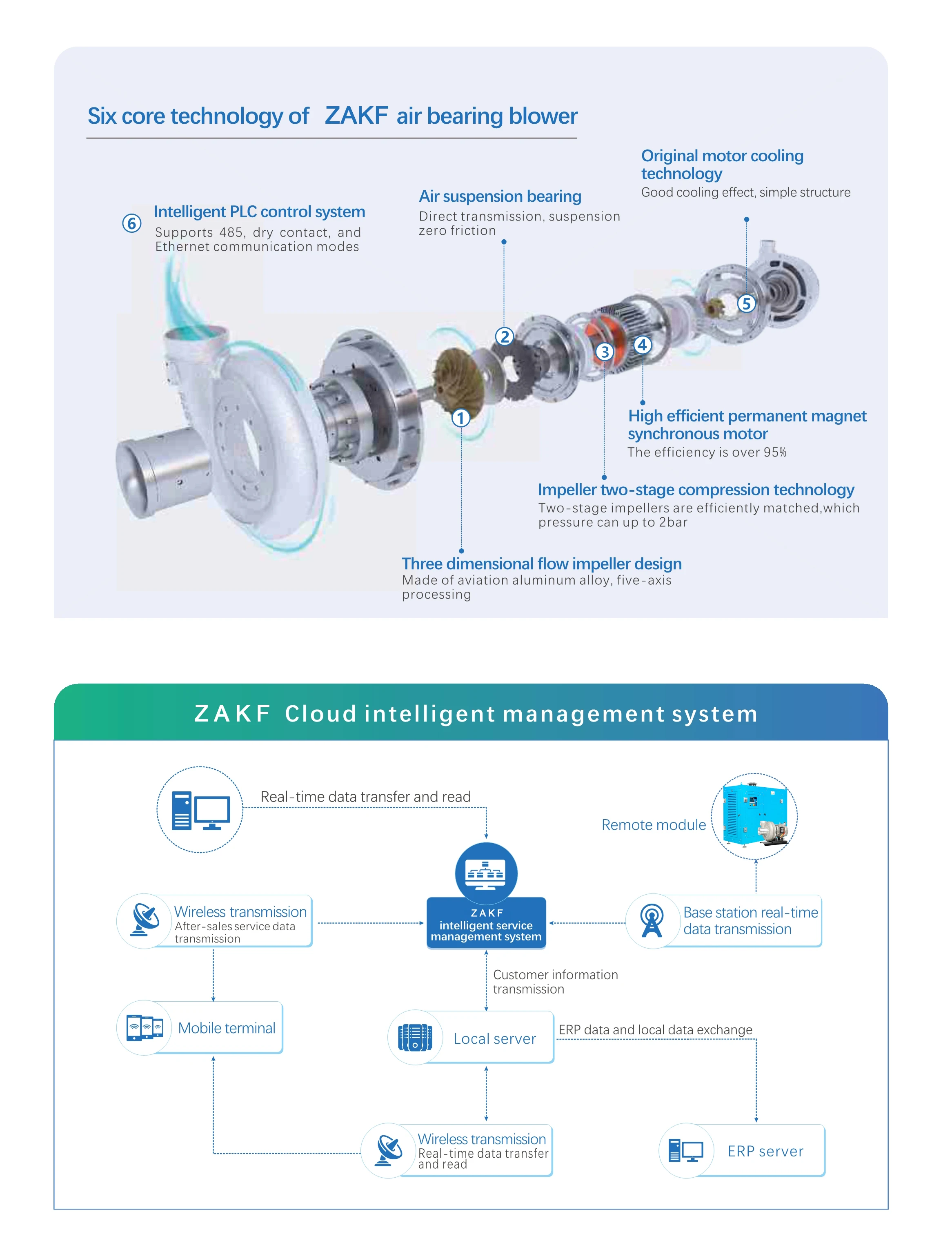

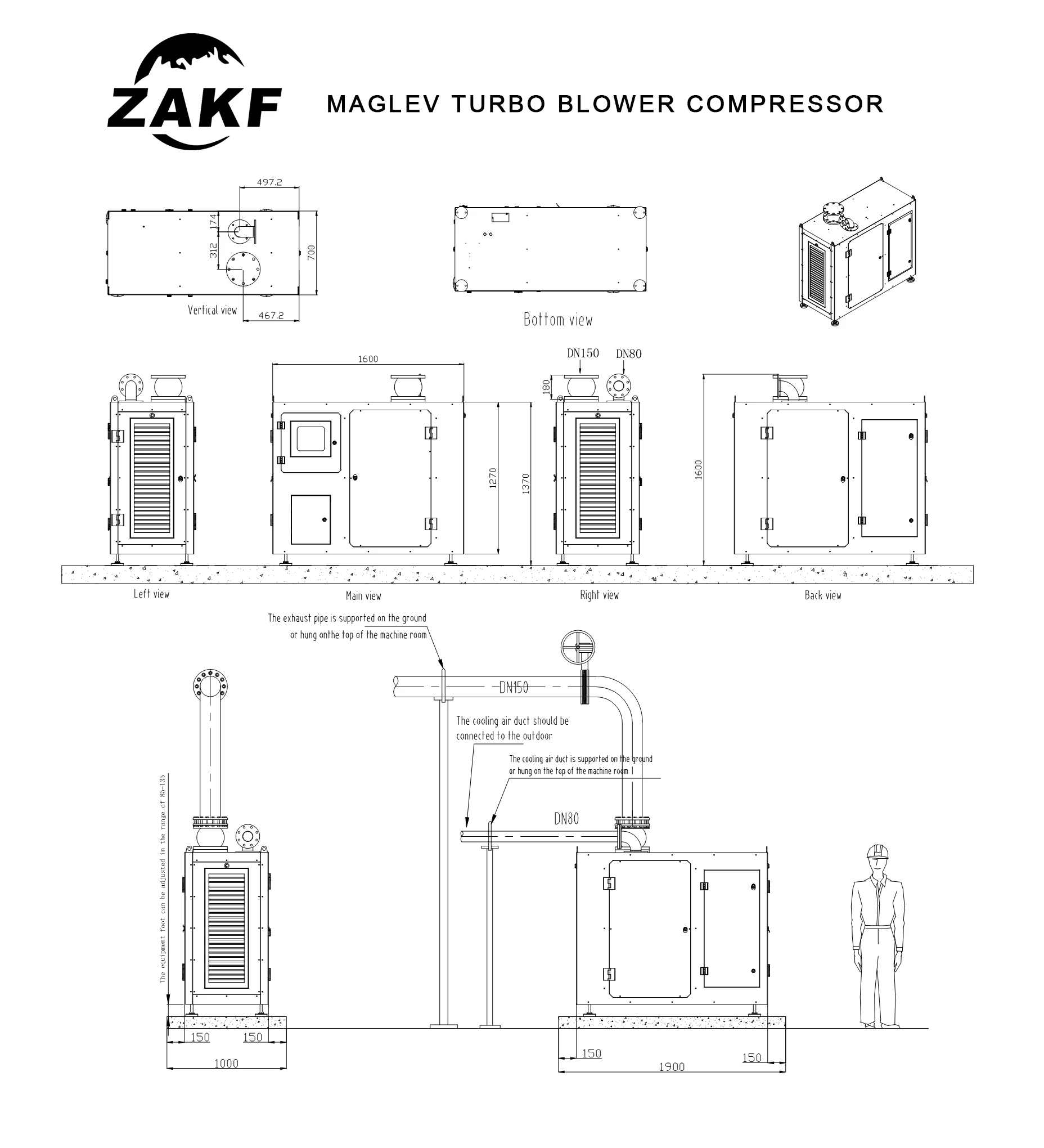

As a leading provider of high-speed turbo machinery, the ZAKF compressor series represents the pinnacle of energy-saving industrial blowers. This 670HP (502KW) model is engineered with advanced magnetic bearing technology, eliminating the need for traditional lubrication systems. Whether you are searching for a ZAKF maglev blower or a high-capacity centrifugal compressor, our ZAKF solutions provide unmatched durability and 130m³/min of high-pressure airflow for demanding industrial applications.

| Compressor type:Maglev air compressor Model:CXPLC670-30 Discharge pressure:3BarG Suction air flow:130m³/min Operating Shaft power:437.4KW Operating Motor Power:455.6KW Operating Total power:474.6KW |

1. Wastewater Treatment:• Aeration is a critical process in wastewater treatment, where air is introduced into the water to promote the growth of microorganisms that break down organic matter. Maglev Turbo Blowers provide efficient and reliable aeration, reducing energy consumption and operating costs.

2. Industrial Processes:• In industries such as chemical, pharmaceutical, and food processing, these blowers can be used for processes that require precise control of airflow and pressure, such as pneumatic conveying, drying, cooling, and ventilation.

3. Aquaculture:• Oxygenation of water in fish farms and other aquaculture facilities is essential for maintaining healthy aquatic environments. Maglev Turbo Blowers can efficiently supply the necessary oxygen levels with minimal energy usage.

4. Landfill Gas Recovery:• Landfills produce methane gas, which can be captured and used as a renewable energy source. Maglev Turbo Blowers help in the extraction and movement of this gas, contributing to more sustainable waste management practices.

5. Biogas Plants:• In biogas production, where organic material is broken down anaerobically to produce biogas, these blowers can assist in mixing and aerating the digestate to enhance the efficiency of the biogas generation process.

6. HVAC Systems:• In large-scale heating, ventilation, and air conditioning (HVAC) systems, Maglev Turbo Blowers can be used for air circulation, providing a more energy-efficient solution compared to traditional fans or blowers.

7. Mining and Mineral Processing:• For dust

| Model | MCC100-20 | MCC100-25 | MCC100-30 | MCC100-35 | MCC100-40 | MCC100-50 | MCC100-60 | |

| HP | (HP) | 100 | ||||||

| Power | (KW) | 75 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 28.5 | 25.5 | 21 | 19 | 17.2 | 15.5 | 14.2 |

| Specific power | 2.63 | 2.94 | 3.57 | 3.95 | 4.36 | 4.84 | 5.28 | |

| Model | MCC150-20 | MCC150-25 | MCC150-30 | MCC150-35 | MCC150-40 | MCC150-50 | MCC150-60 | |

| HP | (HP) | 150 | ||||||

| Power | (KW) | 110 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 42 | 38 | 32 | 29 | 25.5 | 23.5 | 21 |

| Specific power | 2.62 | 2.89 | 3.44 | 3.79 | 4.31 | 4.68 | 5.24 | |

| Model | MCC200-20 | MCC200-25 | MCC200-30 | MCC200-35 | MCC200-40 | MCC200-50 | MCC200-60 | |

| HP | (HP) | 200 | ||||||

| Power | (KW) | 150 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 58 | 52 | 43 | 39 | 35 | 32 | 29 |

| Specific power | 2.59 | 2.88 | 3.49 | 3.85 | 4.29 | 4.69 | 5.17 | |

| Model | MCC250-20 | MCC250-25 | MCC250-30 | MCC250-35 | MCC250-40 | MCC250-50 | MCC250-60 | |

| HP | (HP) | 250 | ||||||

| Power | (KW) | 185 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 72.5 | 64 | 53 | 50 | 45 | 40 | 37 |

| Specific power | 2.55 | 2.89 | 3.49 | 3.70 | 4.11 | 4.63 | 5.00 | |

| Model | MCC300-20 | MCC300-25 | MCC300-30 | MCC300-35 | MCC300-40 | MCC300-50 | MCC300-60 | |

| HP | (HP) | 300 | ||||||

| Power | (KW) | 220 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 88 | 78 | 65 | 61 | 55 | 49.5 | 46 |

| Specific power | 2.50 | 2.82 | 3.38 | 3.61 | 4.00 | 4.44 | 4.78 | |

| Model | MCC400-20 | MCC400-25 | MCC400-30 | MCC400-35 | MCC400-40 | MCC400-50 | MCC400-60 | |

| HP | (HP) | 400 | ||||||

| Power | (KW) | 300 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 121 | 107 | 89 | 84.5 | 75 | 67.5 | 63 |

| Specific power | 2.48 | 2.80 | 3.37 | 3.55 | 4.00 | 4.44 | 4.76 | |

Customer Project

A:we will provie perfect before-sales and after-sales for each machine.

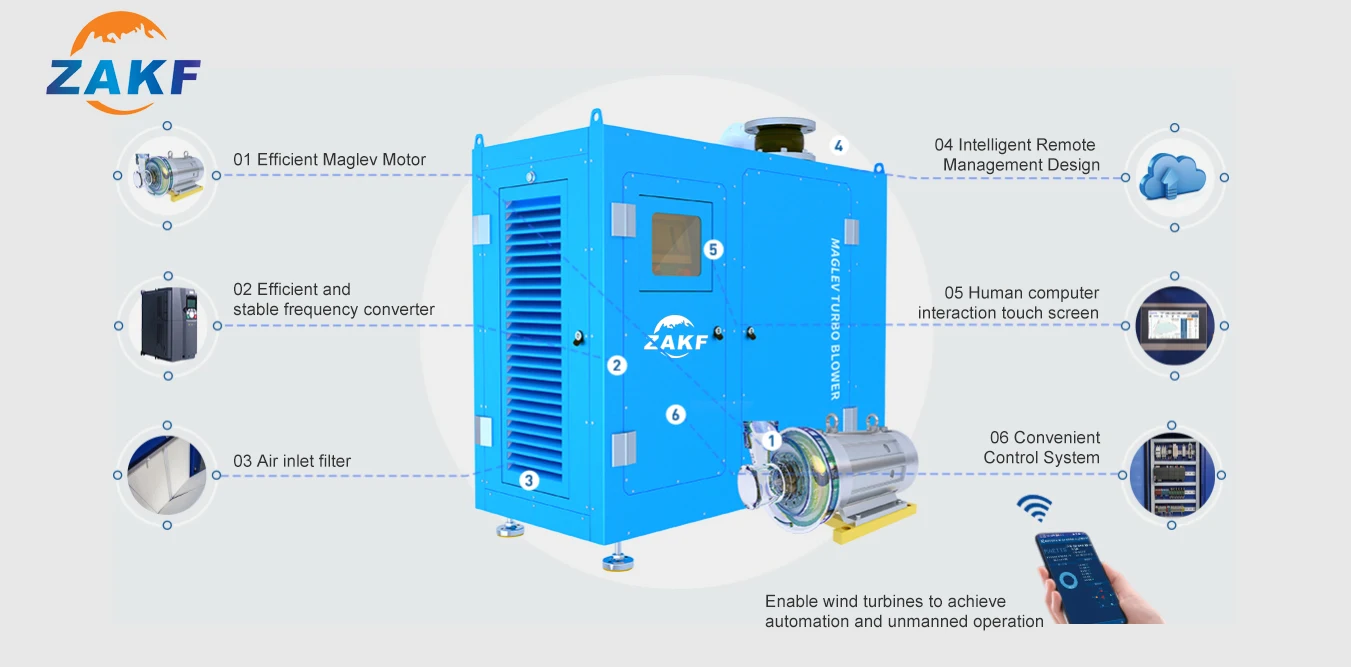

Q: What are the main advantages of a ZAKF magnetic levitation compressor?

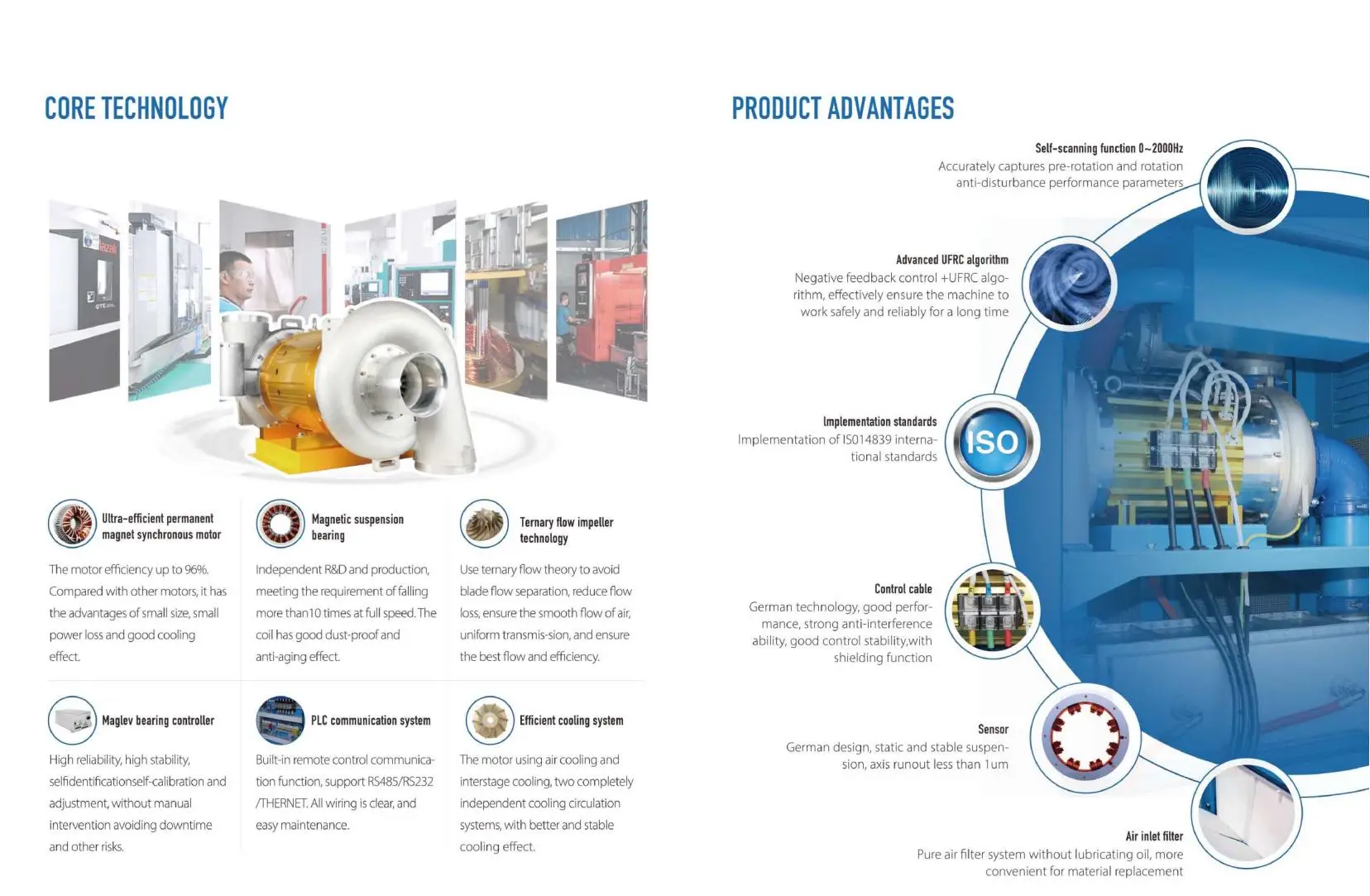

A: ZAKF compressors using Maglev technology offer zero mechanical friction, 100% oil-free operation, and up to 30-40% energy savings compared to traditional centrifugal blowers. They feature low noise (under 80dB) and minimal maintenance requirements.

Q: Which industries are ZAKF compressors suitable for?

A: Our ZAKF magnetic levitation blowers are ideal for wastewater treatment, textile manufacturing, cement production, food processing, and any industry requiring high-volume, high-efficiency oil-free compressed air.

Q: How does the ZAKF 670HP blower ensure energy efficiency?

A: By utilizing a permanent magnet synchronous motor and high-speed frequency conversion technology, the ZAKF compressor adjusts its output in real-time to match demand, significantly reducing power consumption.

As a leading provider of high-speed turbo machinery, the ZAKF compressor series represents the pinnacle of energy-saving industrial blowers. This 670HP (502KW) model is engineered with advanced magnetic bearing technology, eliminating the need for traditional lubrication systems. Whether you are searching for a ZAKF maglev blower or a high-capacity centrifugal compressor, our ZAKF solutions provide unmatched durability and 130m³/min of high-pressure airflow for demanding industrial applications.

| Compressor type:Maglev air compressor Model:CXPLC670-30 Discharge pressure:3BarG Suction air flow:130m³/min Operating Shaft power:437.4KW Operating Motor Power:455.6KW Operating Total power:474.6KW |

1. Wastewater Treatment:• Aeration is a critical process in wastewater treatment, where air is introduced into the water to promote the growth of microorganisms that break down organic matter. Maglev Turbo Blowers provide efficient and reliable aeration, reducing energy consumption and operating costs.

2. Industrial Processes:• In industries such as chemical, pharmaceutical, and food processing, these blowers can be used for processes that require precise control of airflow and pressure, such as pneumatic conveying, drying, cooling, and ventilation.

3. Aquaculture:• Oxygenation of water in fish farms and other aquaculture facilities is essential for maintaining healthy aquatic environments. Maglev Turbo Blowers can efficiently supply the necessary oxygen levels with minimal energy usage.

4. Landfill Gas Recovery:• Landfills produce methane gas, which can be captured and used as a renewable energy source. Maglev Turbo Blowers help in the extraction and movement of this gas, contributing to more sustainable waste management practices.

5. Biogas Plants:• In biogas production, where organic material is broken down anaerobically to produce biogas, these blowers can assist in mixing and aerating the digestate to enhance the efficiency of the biogas generation process.

6. HVAC Systems:• In large-scale heating, ventilation, and air conditioning (HVAC) systems, Maglev Turbo Blowers can be used for air circulation, providing a more energy-efficient solution compared to traditional fans or blowers.

7. Mining and Mineral Processing:• For dust

| Model | MCC100-20 | MCC100-25 | MCC100-30 | MCC100-35 | MCC100-40 | MCC100-50 | MCC100-60 | |

| HP | (HP) | 100 | ||||||

| Power | (KW) | 75 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 28.5 | 25.5 | 21 | 19 | 17.2 | 15.5 | 14.2 |

| Specific power | 2.63 | 2.94 | 3.57 | 3.95 | 4.36 | 4.84 | 5.28 | |

| Model | MCC150-20 | MCC150-25 | MCC150-30 | MCC150-35 | MCC150-40 | MCC150-50 | MCC150-60 | |

| HP | (HP) | 150 | ||||||

| Power | (KW) | 110 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 42 | 38 | 32 | 29 | 25.5 | 23.5 | 21 |

| Specific power | 2.62 | 2.89 | 3.44 | 3.79 | 4.31 | 4.68 | 5.24 | |

| Model | MCC200-20 | MCC200-25 | MCC200-30 | MCC200-35 | MCC200-40 | MCC200-50 | MCC200-60 | |

| HP | (HP) | 200 | ||||||

| Power | (KW) | 150 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 58 | 52 | 43 | 39 | 35 | 32 | 29 |

| Specific power | 2.59 | 2.88 | 3.49 | 3.85 | 4.29 | 4.69 | 5.17 | |

| Model | MCC250-20 | MCC250-25 | MCC250-30 | MCC250-35 | MCC250-40 | MCC250-50 | MCC250-60 | |

| HP | (HP) | 250 | ||||||

| Power | (KW) | 185 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 72.5 | 64 | 53 | 50 | 45 | 40 | 37 |

| Specific power | 2.55 | 2.89 | 3.49 | 3.70 | 4.11 | 4.63 | 5.00 | |

| Model | MCC300-20 | MCC300-25 | MCC300-30 | MCC300-35 | MCC300-40 | MCC300-50 | MCC300-60 | |

| HP | (HP) | 300 | ||||||

| Power | (KW) | 220 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 88 | 78 | 65 | 61 | 55 | 49.5 | 46 |

| Specific power | 2.50 | 2.82 | 3.38 | 3.61 | 4.00 | 4.44 | 4.78 | |

| Model | MCC400-20 | MCC400-25 | MCC400-30 | MCC400-35 | MCC400-40 | MCC400-50 | MCC400-60 | |

| HP | (HP) | 400 | ||||||

| Power | (KW) | 300 | ||||||

| Pressure | (MpaG) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.5 | 0.6 |

| Air flow | (m3/min) | 121 | 107 | 89 | 84.5 | 75 | 67.5 | 63 |

| Specific power | 2.48 | 2.80 | 3.37 | 3.55 | 4.00 | 4.44 | 4.76 | |

Customer Project

A:we will provie perfect before-sales and after-sales for each machine.

Q: What are the main advantages of a ZAKF magnetic levitation compressor?

A: ZAKF compressors using Maglev technology offer zero mechanical friction, 100% oil-free operation, and up to 30-40% energy savings compared to traditional centrifugal blowers. They feature low noise (under 80dB) and minimal maintenance requirements.

Q: Which industries are ZAKF compressors suitable for?

A: Our ZAKF magnetic levitation blowers are ideal for wastewater treatment, textile manufacturing, cement production, food processing, and any industry requiring high-volume, high-efficiency oil-free compressed air.

Q: How does the ZAKF 670HP blower ensure energy efficiency?

A: By utilizing a permanent magnet synchronous motor and high-speed frequency conversion technology, the ZAKF compressor adjusts its output in real-time to match demand, significantly reducing power consumption.